high accuracy evolution

Buried inside the 5 phone books delivered with new Speedios is documentation about a major evolution lying dormant in the C-00 control. What’s going on?

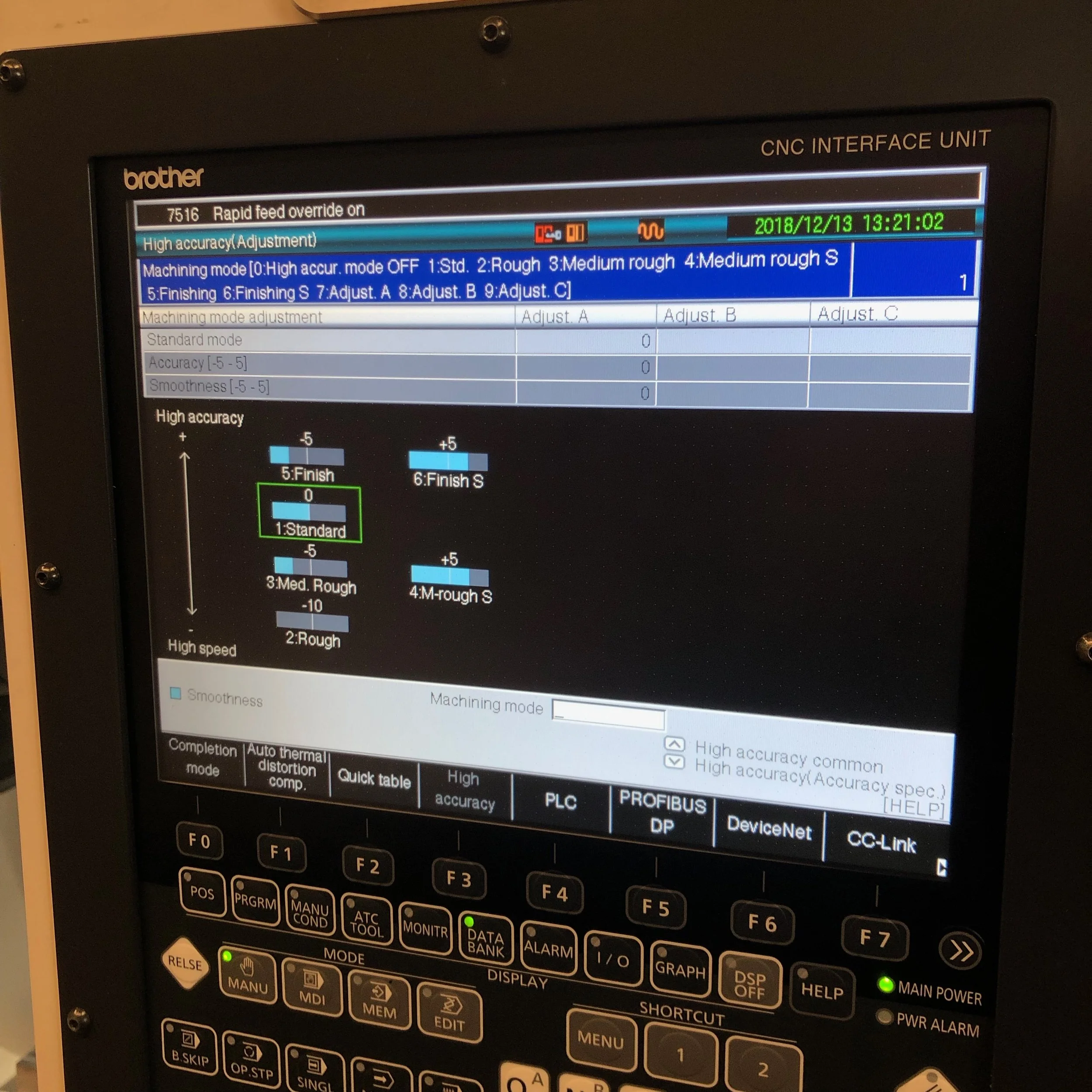

High Accuracy Quick Setting

Brother’s original High Accuracy interface has been a bit of a sticking point as these machines have gained popularity amongst the unique needs of the US market. Where Haas mills, Robodrills, and Okuma machines automate and simplify the application of their code smoothing technologies, High Accuracy’s unique focus on deep configurability for a specific application makes the system a complex hinderance in quick-turn environments.

Brother is clearly aware of this situation and has, without announcement, completely redesigned the interface for High Accuracy to bring both the operator and programming interface in-line with other machines in this market. These settings are present in (we believe) firmware above v8.000, but are not turned on by default and the driving parameters for the individual strategies are not populated in the machine parameters.

What’s New?

Machining Strategies:

Confusing strategy M codes have been replaced with a new set of named machining strategies:

Rough

Medium Rough

Medium Rough S

Finishing

Finishing S

Standard

The "Standard" strategy replicates Haas G187 P2 or the Fanuc "Standard Accuracy" those machines have set as the factory default for general purpose applications.

Medium Rough S and Finishing S are intended for complex geometry (3D surfaces or spline driven contours).

These strategies continue to use Mode A and Mode B algorithms, but the difference between the two is now invisible at the operator/programmer level. In fact, the new Factory settings only utilize Mode B for the two Finishing strategies.

Optimized Settings:

If you've delved into Mode A or Mode B parameters on the Speedio, they have the appearance of essentially being placeholders. Brother always intended High Accuracy use to be tuned on a per-application basis by end users. With the new strategies, Brother is now delivering real parameters designed to work as the names imply. In our very initial tests, we're seeing dramatic performance improvements:

Rough is performing within 6-12% of the speed of raw code, while delivering enough accuracy to leave 0.02" of stock without model violation. By comparison, the former best Mode B roughing we could achieve was a 35% performance hit to apply High Accuracy.

Finishing has a significant performance boost, while improving overall smoothness, entry/exit witness lines, and produces crisp text at high speed on engraving applications.

Finishing S is showing improved smoothness and accelleration in 3D surface tests, while cutting cycle time by 20% compared to the older M281 code.

High Accuracy Quick Setting Pages:

Once activated, the most visible component of the new interface is the Quick Setting page in User Parameters / High Accuracy (it is below the older Mode A and B setting pages). Here, users can:

Select the machine’s default strategy.

Create/modify user tweaked Adjust 1/2/3 modes on the fly

Select a default Accuracy Specification (on page 2)

Set the tolerance limits for each of the 3 accuracy specifications (also on page 2)

Default Mode:

The new Quick Setting screen allows the operator to select a default strategy for the machine to automatically execute all code in during operation, without having to modify that program with M-codes. Brother has configured a “Standard” setting that balances speed, accuracy, and smoothness with the clear intent of making it the “Set it and forget it” strategy, similar to how Haas configures all mills to automatically use G187 P2. Alternatively, the Accuracy Spec page allows users to select one of the 3 accuracy specifications to be set as the default (users can only select one default, activating both will cause an alarm).

New M Codes:

Programmers still need control of smoothing in code, so Brother has consolidated the 18 combined Mode A/B codes into a new set of override M codes. M298 Ln is used to select any strategy to override the default, M299 cancels this override. Importantly, M299 does not turn off high accuracy, it simply reverts to the default the user has selected. For sections of code that need to run without smoothing (i.e. probing or some macro programs), it is important to use the M298 L0 code to insure this happens with complete reliability. Program end or reset will reset any code overrides and set the machine back to the selected default, so modifying probing macros only requires the M298 L0 at the top.

The new codes are:

L0 High Accuracy Off

L1 Standard

L2 Rough

L3 Medium Rough

L4 Medium Rough S

L5 Finishing

L6 Finishing S

L7/8/9 Adjust A/B/C

L21/22/23 Accuracy Specification A/B/C

Automatic Tolerance Modes:

Brother now offers 3 Accuracy Spec strategies that allow a user to specify a tolerance and all code executed will stay within the path to that tolerance without exception. The control handles all other settings automatically. These are Accuracy Specifications A/B/C, and can similarly be used in programs using the M298 Ln codes.

Operator Adjust Settings:

The Quick Setting screen allows users to create tweaked strategies on the fly by picking one of the 6 factory settings and adjusting 10 steps (+5/-5) of Accuracy and Smoothness. Once created, Adjust A/B/C modes can be selected as the default or called in a program with M298 L. The impact of the +/- stops is controlled in the parameters for the primary 6 factory strategies.

Backwards Compatible:

Current Mode A and Mode B settings remain fully intact and still work as normal. G-code programs that have the old M codes (M285, M281, etc) will continue to pull their settings from the same User Parameter pages as before. In a program, these codes will override the default function, and an M269/M289 will revert to the default setting from the new Quick Setting pages.

Turning This On

The good news is that the new High Accuracy system is fully baked and has been in Speedio firmware since (we believe) version 8.01. Machines delivered over the last year have had 8.05, but most have the new system turned off and the strategy parameters left blank. We know of one recent delivery S500 that arrived with the system turned on and parameters fully set.

If you have a machine that was delivered with Firmware 8.01+, refer to your printed Instillation Manual for the Machine Parameters listing. The High Accuracy section lists all parameters for both High Accuracy Common, plus all of the machine strategy parameters. The Common parameters will all be set to go, but most will need to go through the Standard/Rough/Medium Rough/etc pages and input the parameters from the install manual.

The setting to turn the system on is Parameter 8103 - Basic Setting Function. Enable this with a 1.

There is one modification from the standard Common parameters that must be made; 8003 Reference Feedrate A needs to be increased to at least 20,000mm/min. We’ve been performing all our testing with this parameter set at 30,000mm/min, as well as the Mode A Max feedrate at 30,000mm/min (Parameter 8004). These parameters will enable the Rough/Medium Rough strategies to feed at up to 755IPM (though accuracy will deteriorate when you get to those speeds).

Of course, if your machine is over a year old (as of December 2018 when this is written), you will need to obtain a firmware upgrade. Be aware that Brother only has firmware 8.01 available to Yamazen for field upgrades at this time. Yamazen can provide you with firmware for a DIY update, but it is a tricky operation and they tend to prefer having a technician do it during a service call. At this time, there is a pending update from Brother that will also enable some other important functionality (G/M codes with custom macros in the MDI for one, a game changer for setup work and general use). As such my recommendation is to hold your horses for few more weeks before going through the firmware update rigamarole.

Application Notes

The Standard Strategy

For those of you who don’t want to mess with all this High Accuracy business, setting the machine up to use the Standard strategy as the default is actually quite effective. We’ve found no issues running our current parts with this set as the default, though it does obviously lose significantly on parts with significant material removal during roughing cycles from bar stock. Just as the majority of Haas and Robodrill owners never mess with any of this and get solid results, the Speedio now comes (basically) out of the box prepared to perform quite well in a broad range of circumstances.

Since our post has not been modified to use the new codes, we’ve been running production parts with the machine in Standard as the default, and manually apply Rough to the appropriate operations and have seen a 12% cycle time reduction with these two changed alone. For anyone doing work in the +/- 0.002” standard job shop range, Standard is the perfect balance of smoothing, cycle time, and accuracy. In fact, most of our testing shows minimal difference in any strategy setting at feeds below about 100IPM.

Mode B Misconceptions

With the Speedio’s introduction of Mode B, most were under the natural impression that these new algorithms existed to replace Mode A. In fact, Brother uses Mode A for Standard, Rough, Medium Rough/S. Mode B is only applied for the two finishing codes. Even with all the new insights, we have been absolutely unable to get Mode B to perform roughing or medium roughing type applications with anywhere near the smoothness or speed of the Mode A driven factory strategies.

It is also clear that the Mode BII upgrade (to 200 blocks of look ahed) is likely unnecessary for the vast majority of users. Mode B look ahed exists purely for the sake of calculating accurate paths through segments of tiny G01 moves. This increased look ahed will only come into play for those throwing huge piles of the densest possible code at these machines in very specialty finishing applications. Even with extensive testa designed to choke the machine’s code processing ability (high speed roughing toolpath, with no CAM smoothing/arc filtering, and tolerance of 0.0001”), we have been absolutely unable to slow the machine down or find circumstances where the control cannot keep up.

Mystery Smoothing

The control also features a series of mysterious M380 series codes for 3D surfacing. The user parameters outline the ability to tell the machine the path stepover, center of the work, and some other variables, but the rest of the functionality is totally undocumented. We believe that this feature is what the marketing material for the Speedio indicates as the enhanced smoothing functions of the BII upgrade.

Probing

If you do utilize the new High Accuracy system, be aware that part and tool probing macros will need to be modified with the M298 L0 code. You may also need to modify CAM posts that offer in-process probing. In many cases, the machine will perform probing without throwing an alarm, but you will notice errors and inaccuracies in the results. Some circumstances, an alarm will be thrown by the probing macro if it detects any funny business with feed rates during the critical skip signal movements used for measurement.